3D-CFD Simulation

|

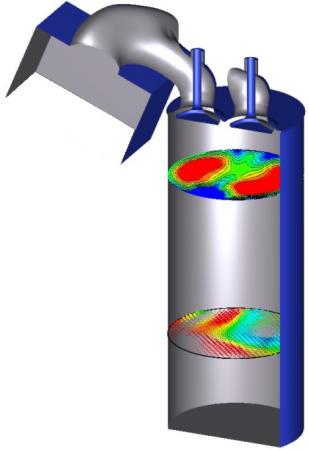

HERON offers applied thermodynamics and computational fluid dynamics (CFD) simulation work inside internal combustion engines for our clients worldwide. 3D-CFD simulations allow a "virtual view" into the engine, either into the inlet port or directly into the combustion chamber for the mixture preparation. Our expertise is based on long-term experience, mainly in the field of big-bore diesel and gas engines as well as high-performance racing engines.

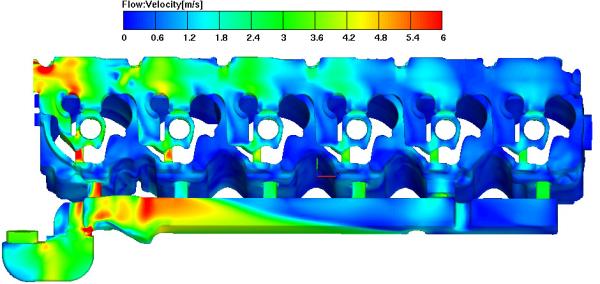

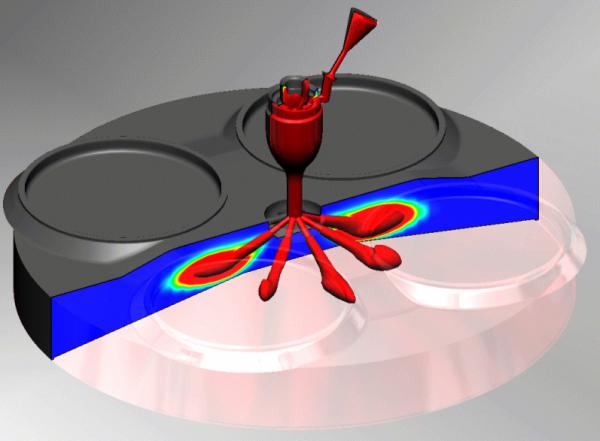

· Virtual flow bench simulation · Fuel injection and combustion simulation · Coolant flow in cylinder heads

...with the tasks of predicting and optimising

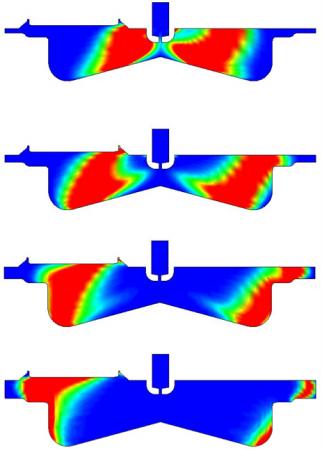

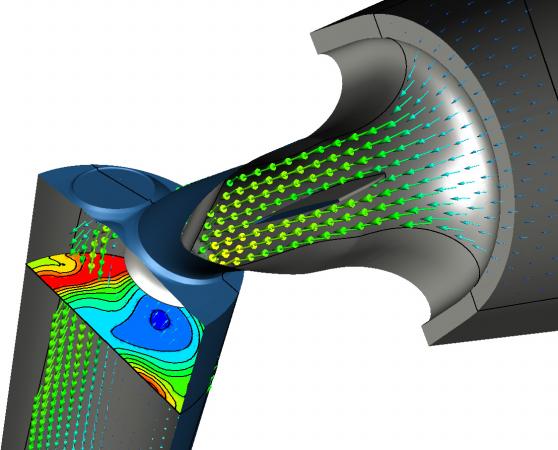

· Flow coefficients (μß or αΚ) for inlet and exhaust ports and calculation of swirl and tumble values · Entire gas exchange process with moving valves and piston · Diesel or Otto combustion simulation · Calculation of knocking probability · Simulation of fuel injection (e.g., common port injection, high-pressure direct injection or fuel fed pre-chambers)

Applied procedure:

· Surface preparation based on STL or any other CAD data format · Automatic, semi-automatic or manual mesh generation depending on the task complexity (e.g., valve gap area, tiny pre-chamber design or spray of injection) · Determination and application of boundary conditions as defined by 1D gas exchange simulations or measurement from the test bed · Execution of the calculation on multicore computers · Plausibility checks (mean pressure and temperature, IMEP, µσ, ...) · Post-processing of calculated results by 2D graphs, flow pattern visualisation and video animation · Report generation with diagrams and videos

|

|

|

|

|

|